T

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

snobuilder

Well-known member

finally something REAL from the trcker.

T

Tracker

Guest

finally something REAL from the trcker.

haha.....I assure you all I say is real...some fortunate and some unfortunate but ALL are life experiences...even the bigfeets

T

Tracker

Guest

With a toolpost that you can stand on, hopefully not when running as not much room to dodge the chunks (chips) that would be flying.

and you have to use a sledge hammer to turn the feed on and off....and avoiding chips....not possible....I wore my high school leather jacket to keep them off of me....but they would hit you hard...I mean really hard and a puff of nasty smoke off the leather being burned would be in the air....each little chip would sound like a baseball bat homerun and the edges would have 1/4 inch molten orange hot ball bearings flying randomly in all directions....heres some chips I did...3/4 depth by 3/8 feed each pass.....would bring the building almost down because it was 3 heads at once....when it hit at 3/4 deep....it would stall for 1 second and then the freight train would come and the concrete would rumble....the most force you could ever imagine with a deep gear hunker down sound....filled 1 wheel barrow of smoking hot purple chips every half hour...if one hit you in the head...say goodbye...I was the KING OF DODGE BALL....lmao...you changed gears by going inside the motor and saying...BENNIE....give a 64 tooth gear will ya...and don't turn on the machine or I will haunt you when I die...LOL...see the last pic...those molten rays of steel points...on the end of each one was the molten 1/4 round ball bearings coming off it was so hot it was unbelieveable....2 chips were like 5 inches long...and that last pic is how they were coming off the tool in succession like that....I was the only one willing to run this thing at full tilt and 3 heads at once

T

Tracker

Guest

heres is just cutting a basic journal...see the dude in blue overalls...that's ED....he was 21 and I taught him how to run the thing....we were doing 4 foot cam shaft with 4 foot lobes and 4 foot swing....you had to get yer head in to see cut...then back out for lobe to swing....beyond dangerous....I learnt from this that trees are soft...LOL...overall...LOL

update...sorry that's not eddie....but it is the same journals and lathe...I thought I saved em all....looking for more smedberg films but there aren't any

update...sorry that's not eddie....but it is the same journals and lathe...I thought I saved em all....looking for more smedberg films but there aren't any

Last edited:

T

Tracker

Guest

bennie was a kid I was training as a helper for the 6" G&L....and ken smedberg was an awesome boss....the place went out of business unfortunately....a part of America that was a huge asset IMO...look behind Kenny when he talks at the size of those ANGLE IRONS for the machine....12 feet tall...weighs tons...I once drove an enormous dual wheeled forklift down stony island to 79th to "LEONS RIBS" at 2am for lunch...you shoulda seen the people swerving and the looks...panic....cops never came...got me rib tips and left

like this big...LMAO

like this big...LMAO

T

Tracker

Guest

ok heres eddie flipping over a crane housing he was line boring....there is the gear in the back ground...its red....this is the G&L I used to run

- - - Updated - - -

boring it out

- - - Updated - - -

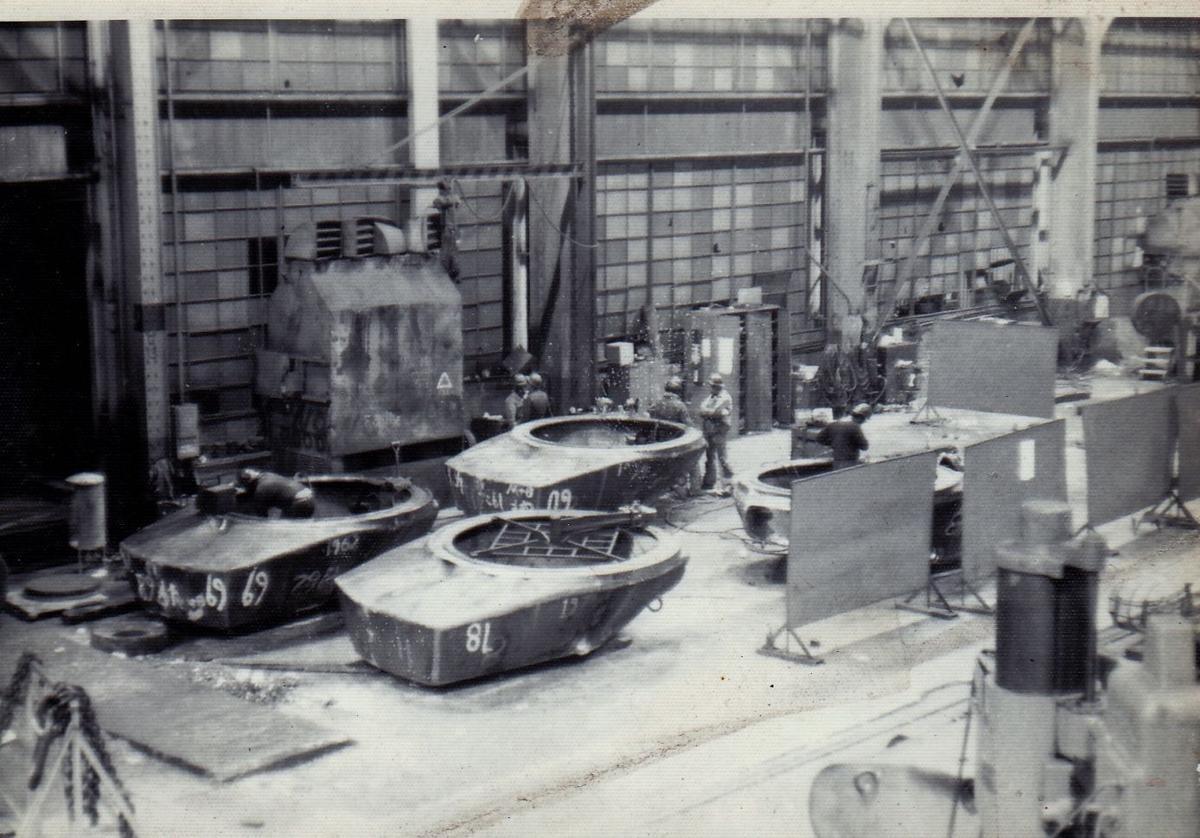

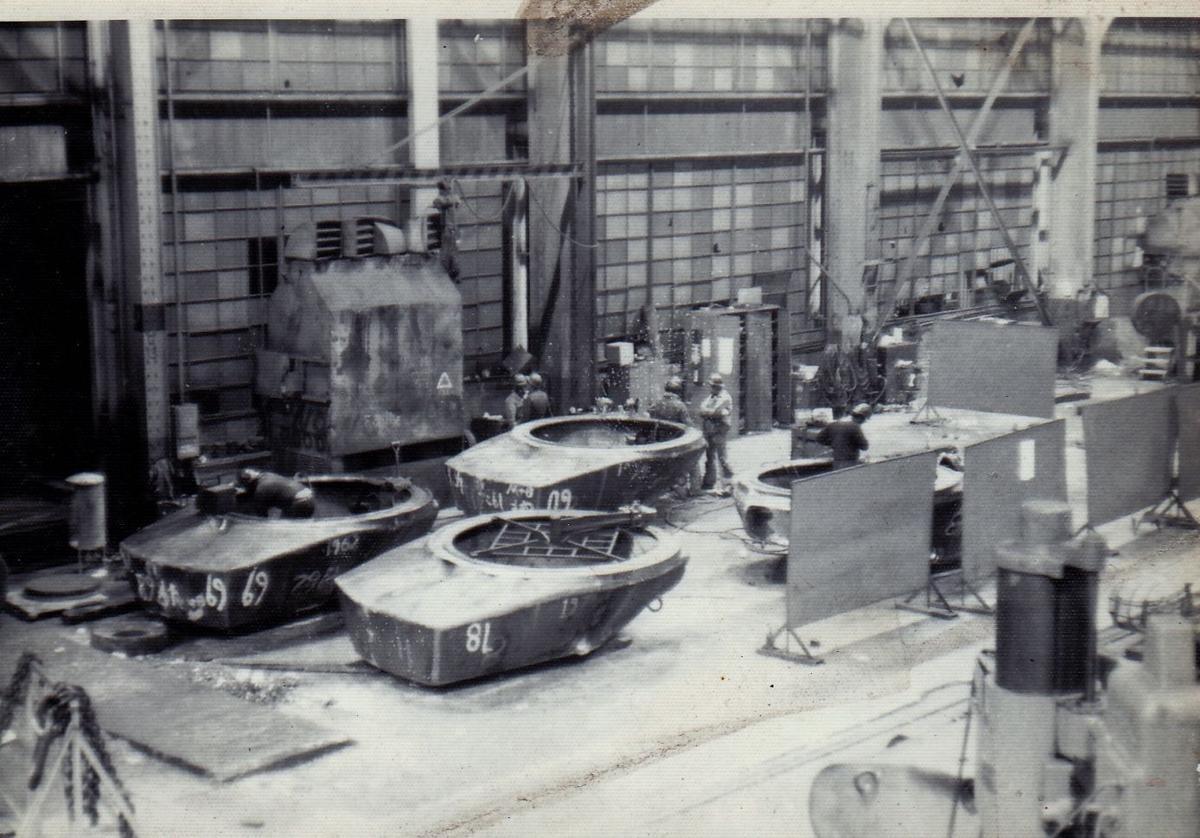

took apprenticeship here...at BLAW KNOX east Chicago Indiana making M60/M1-A1 abrams tanks...an old pic but it shows the size of stuff

- - - Updated - - -

boring it out

- - - Updated - - -

took apprenticeship here...at BLAW KNOX east Chicago Indiana making M60/M1-A1 abrams tanks...an old pic but it shows the size of stuff

sweeperguy

Active member

What kind of tolerances do you work within, on parts that big.

Is it bigger parts larger tolerances?

When I was machining, a lot of parts we milled were +/- .005

We did some hard drive parts for Seagate that had tolerances in the ten thousandths.

Is it bigger parts larger tolerances?

When I was machining, a lot of parts we milled were +/- .005

We did some hard drive parts for Seagate that had tolerances in the ten thousandths.

SledTL

Active member

Common tolerances for most machining is +/- .005, but a lot of the medical device stuff is in the +/- .0005 range. Crazy tight when you are talking about the width of less than your hair in difference. Tracker what is the cycle time on one of those large gears? Better have some good trust in your machinists, because one offset gets screwed up and you are talking huge $$ in scrap.

C

Cirrus_Driver

Guest

Common tolerances for most machining is +/- .005, but a lot of the medical device stuff is in the +/- .0005 range. Crazy tight when you are talking about the width of less than your hair in difference. Tracker what is the cycle time on one of those large gears? Better have some good trust in your machinists, because one offset gets screwed up and you are talking huge $$ in scrap.

Not only RUN cycle times, but setup times for the machine, and more importantly LOT SIZES to amortize the setup, and last but not least - the machine center Direct Labor and Overhead, RATE PER HR.

My life - for only another 48 weeks, thank GOD.

sweeperguy

Active member

Common tolerances for most machining is +/- .005, but a lot of the medical device stuff is in the +/- .0005 range. Crazy tight when you are talking about the width of less than your hair in difference. Tracker what is the cycle time on one of those large gears? Better have some good trust in your machinists, because one offset gets screwed up and you are talking huge $$ in scrap.

Yep. That's why I wondered if large pieces like that ran similar tolerances.

SledTL

Active member

Yep. That's why I wondered if large pieces like that ran similar tolerances.

I would imagine that the spots where the gears meet have a pretty high tolerance otherwise you could shear metal off. For other features probably more lax.

snobuilder

Well-known member

....OK i'll say it......is that a Yamaha Apex counterbalancer?

T

Tracker

Guest

What kind of tolerances do you work within, on parts that big.

Is it bigger parts larger tolerances?

When I was machining, a lot of parts we milled were +/- .005

We did some hard drive parts for Seagate that had tolerances in the ten thousandths.

yes the tolerances vary for applications but basically the bigger is more tolerance....I think that one was .003....the line bores can be .0005 tenths...and one piece I recently did was +/- 1 micron.... I had 1 micron taper on it...turned out beautiful...was a small part.....the setup can be days on huge shat....just one finishing cut can take 2 days....8 hour shifts.....3 shifts

got o admit that big stuff is just amazing

my father worked for Chrysler. then general Dynamic's making tanks,(and other things) got many tours over the yrs of things in process

it still amazes me how it all gets done and the skills behind making them, hats off to you there Tracker!

maybe you need to machine out a big foot live trap?? that's portable however!

LOL

my father worked for Chrysler. then general Dynamic's making tanks,(and other things) got many tours over the yrs of things in process

it still amazes me how it all gets done and the skills behind making them, hats off to you there Tracker!

maybe you need to machine out a big foot live trap?? that's portable however!

LOL

T

Tracker

Guest

One micron taper by turning? We deal in microns every day but not by turning as we leave that to grinding.

no I was just stating a tolerance....I did that on a WEDM...and yes on that big stuff you do a tool post grinder setup to dial it in close...gears range from .01 grand to .02 grand and closer depending on application

T

Tracker

Guest

those gears were mainly for roll tables in the mills

https://www.youtube.com/watch?v=AuuP8L-WppI

- - - Updated - - -

this guy almost got killed when one failed

https://www.youtube.com/watch?v=atF0D97dKeY

https://www.youtube.com/watch?v=AuuP8L-WppI

- - - Updated - - -

this guy almost got killed when one failed

https://www.youtube.com/watch?v=atF0D97dKeY

T

Tracker

Guest

here is a crank shaft being made....this is why smedbergs went out of business.....workers...half pay....no safety at all