Do you think the 0.100" gap on the secondary is enough to mess with? I had never checked it previously, the sled was in an accident with a bus that caused the pipe to get pushed/dragged in the direction that the motor is twisted, I suspect that is where the twist came from. The motor may have always been twisted this way I just had never checked. I am fairly certain I can get the mag side motor mount out to modify it without pulling the motor but not so sure about the drive side mount, and with a trip coming in 2 weeks I don’t want to create any additional problems.

Thanks for the link good reading

1) .100" is too much , I.M.O.

2) BEFORE you do anything else, gotta check the center to center first, as this WILL affect the amount to slot the engine bracket holes. Slotting them with a 3/8" or so coarse rat tail file goes pretty quickly, not even a need for the air tools

3) I have done this job in half day removing the engine, re-installing, re-checking etc

And I have done it in 2 1/2 hours by leaving the engine in the sled, ALL hoses, wiring still connected. By this method, you remove the air-box, unbolt the 4 motor mounts, and securely place wood blocks under the engine and raise the engine as high as possible so you can get underneath it to remove the 4 bolts that attach the engine brackets to the engine . You don't even drain the anti-freeze, and no mess.

It's a P.I.T.A. to do it this way, (preferably need the assisstance of someone with small hands to get at the bolts, had my bud's son help with this) but saves time & mess, and honestly the worst part of the engine R & R on these CFI's is figuring out where all the wires go.

If you measure your C/C, I can provide you with the correct amount to slot the engine bracket holes so you can do this job once, rather than going back & forth.

ALSO-VERY IMPORTANT:

1) Please advise if you're going to use that SLP MAG side engine limiter. It's approx $ 25.00 and a 5 minute install, HIGHLY recommended, and affects the amount of "twist"

2) Send out your clutch to have it balanced, extends engine life. Indy Dan in Minnesota can handle this for you.

3) Set the primary clutch belt to sheave clearance at around .010" to .015" . This improves acceleration and reduces the slamming effect on the crank upon engagement. Indy Dan in Minnesota can handle this for you.

4) Using 180 grit, SAND the faces of BOTH clutches perpendicular to the way the belt rides and wipe down with lacquer thinner or brake-clean

5) Install NEW POLARIS springs in BOTH clutches, at the beginning of each and every season.

6) Purchase a NEW Polaris belt WASH AND SCRUB in hot soapy water and let dry thoroughly. Sounds weird, but this removes the slippery mold release compound that would otherwise get smeared all over your nice clean clutches.

You'll be amazed how much better your sled runs, and how long your belt will last by doing the above.

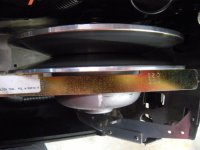

Left Pic below is my old 2007 DRAGON 700 primary before I corrected engine alignment. Note the belt does not come up to the top as it should (for a flat-lander sled)

Lower right pic below is the SLP PUSH limiter, MAG side mount, butts up against recoil housing, 2 holes to drill, E-Z install!