although aluminum is impervious to rust, it is still open to corrosion not to mention a steel axle being bolted to it. This weekend I picked up my new Catalyst and once back to the shop I noticed a tilt to my rear left wheel on my trailer which is an inline enclosed steel framed trailer. it is from 2007 and years of parking it behind shop in the grass (which probably was not a good idea) finally took its toll. the rear axle had broke in half, tore the front of the axle mount from frame, twisted the rear, while under there noticed the front r/h axle mount is also separating from the frame and the bottom of that torsion axle is also split wide open and rotted as well. luckily I made it home without a trailer disaster on the interstate. Im going to retire the trailer for storage here and buy an aluminum trailer, I have had them in the past but my question is, does anyone spray the underside of frame with any kind of metal protector? and if so what do you use or have luck with?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Aluminum trailer care

- Thread starter euphoric1

- Start date

Old farmer taught me to smear grease with a old glove EVERYWHERE. Also I spray trans fluid into nooks and crannies. As far as the frame to axle, or any other steel to aluminum joint, make sure there is some type of isolator. My buddy makes me these shims, if you will, about .125 thick out of HDPE plastic, then I cut to fit as needed. Best of luck with your new toys.

I hope you bought a lottery ticket because that was your lucky day for making it home with a trailer as you describe.

I've tried a couple of different things except for the grease which sounds like a Holy Mess. I try to wash mine regularly after use in the salt. Definitely at the end of the season. Once cleaned with pressure washer I spray the underside with liquid wax. Hitting the areas of axle and where the steel meets the aluminum. Salt and Age are the worst enemies of trailers in my opinion. We can't do much about aging but by keeping them as clean as possible helps.

You got 16 years out of your old trailer, that's pretty good but that New Cat deserves a new trailer, make it happen!

A postscript regarding trailers, last year about this time I got the idea of checking out my trailer, lights, wiring, hitch, etc. By chance I put a wrench on one of the lug nuts and I got a full 360 before it snugged. I went to the next one, same thing. Every lug nut on my trailer was loose by a complete turn, if not more. Is it time to check yours?

I've tried a couple of different things except for the grease which sounds like a Holy Mess. I try to wash mine regularly after use in the salt. Definitely at the end of the season. Once cleaned with pressure washer I spray the underside with liquid wax. Hitting the areas of axle and where the steel meets the aluminum. Salt and Age are the worst enemies of trailers in my opinion. We can't do much about aging but by keeping them as clean as possible helps.

You got 16 years out of your old trailer, that's pretty good but that New Cat deserves a new trailer, make it happen!

A postscript regarding trailers, last year about this time I got the idea of checking out my trailer, lights, wiring, hitch, etc. By chance I put a wrench on one of the lug nuts and I got a full 360 before it snugged. I went to the next one, same thing. Every lug nut on my trailer was loose by a complete turn, if not more. Is it time to check yours?

indy_500

Well-known member

Like mentioned, preseason and postseason I take a latex glove and smear marine grease all over the axles and all around the mount area where the axle meets the frame, then spray fluid film in the nooks and crannies and all over the leafs/hardware/brakes. I take my trailer to a manual car wash after every use, and I also 2-3 good underside cleanings with a pressure washer before storing for the summer. And yes, keeping them away from moist ground for summer storage is key. Might seem a bit overboard, but for how much these things cost, and the terrible conditions we pull them thru, my mind seems it necessary

Last edited:

dfattack

Well-known member

Gary are you using a torque wrench and torquing them to the required amount?I hope you bought a lottery ticket because that was your lucky day for making it home with a trailer as you describe.

I've tried a couple of different things except for the grease which sounds like a Holy Mess. I try to wash mine regularly after use in the salt. Definitely at the end of the season. Once cleaned with pressure washer I spray the underside with liquid wax. Hitting the areas of axle and where the steel meets the aluminum. Salt and Age are the worst enemies of trailers in my opinion. We can't do much about aging but by keeping them as clean as possible helps.

You got 16 years out of your old trailer, that's pretty good but that New Cat deserves a new trailer, make it happen!

A postscript regarding trailers, last year about this time I got the idea of checking out my trailer, lights, wiring, hitch, etc. By chance I put a wrench on one of the lug nuts and I got a full 360 before it snugged. I went to the next one, same thing. Every lug nut on my trailer was loose by a complete turn, if not more. Is it time to check yours?

I am going to check for that insulator between axle and frame as dislike metals don't always mix, buddy of mine found thot out with a Triton trailer, interesting that you add a spacer and thank you for the information, I do like the marine grease idea, I don't know if its available anymore but knew there were products like "fluid film" or "LP3" at one time. Thank you!Old farmer taught me to smear grease with a old glove EVERYWHERE. Also I spray trans fluid into nooks and crannies. As far as the frame to axle, or any other steel to aluminum joint, make sure there is some type of isolator. My buddy makes me these shims, if you will, about .125 thick out of HDPE plastic, then I cut to fit as needed. Best of luck with your new toys.

never a bit overboard and yes was not a good decision to park in back 40 and my fault for doing so and not inspecting and as Gary said I should buy a lotto ticket as i think the only thing keeping it from completely separating is the internal spring. Thank you for the input! Much appreciated!!Like mentioned, preseason and postseason I take a latex glove and smear marine grease all over the axles and all around the mount area where the axle meets the frame, then spray fluid film in the nooks and crannies and all over the leafs/hardware/brakes. I take my trailer to a manual car wash after every use, and I also 2-3 good underside cleanings with a pressure washer before storing for the summer. And yes, keeping them away from moist ground for summer storage is key. Might seem a bit overboard, but for how much these things cost, and the terrible conditions we pull them thru, my mind seems it necessary

Yes, I do now. It's part of my planned maintenance each year.Gary are you using a torque wrench and torquing them to the required amount?

indy_500

Well-known member

Also figured I’d mention, I used to own a 7x23 stealth. After 3 hard years of use by the previous owner, I did a complete overhaul, took the axles off and did new bearings brakes leafs hardware etc por 15’ed the axles etc. after just 3 years the frame where the axle bolts was was HEAVILY corroded. Definitely concerning. After all the repairs, I used roofing tar tape to put between the two dissimilar metals.

that would work too! provide a good insulating point. i guarantee you most people don't think about that point, even manufacturers, just as I didn't parking in the grass lolAlso figured I’d mention, I used to own a 7x23 stealth. After 3 hard years of use by the previous owner, I did a complete overhaul, took the axles off and did new bearings brakes leafs hardware etc por 15’ed the axles etc. after just 3 years the frame where the axle bolts was was HEAVILY corroded. Definitely concerning. After all the repairs, I used roofing tar tape to put between the two dissimilar metals.

Dirty70Firebird

Member

spray underside with Fluid Film, there are others that might be cheaper, but Fluid Film works well.

I think our Legend is about 10 years old now. We've hosed it off at the car wash after nearly every trip and had to redo all the brakes once do to corrosion, but we haven't done much else to it. I did coat the bottom with fluid film year 1 but didn't keep up with it.

I'm guessing it will need to be refreshed soon with new axles and probably new brakes at some point soon. I know the tires are due as we noticed a bit of dry rot this spring, and I need to start looking into those. Only bought trailer tires for a little 2 place. Other than the door latches getting rusty it looks good otherwise.

I'm guessing it will need to be refreshed soon with new axles and probably new brakes at some point soon. I know the tires are due as we noticed a bit of dry rot this spring, and I need to start looking into those. Only bought trailer tires for a little 2 place. Other than the door latches getting rusty it looks good otherwise.

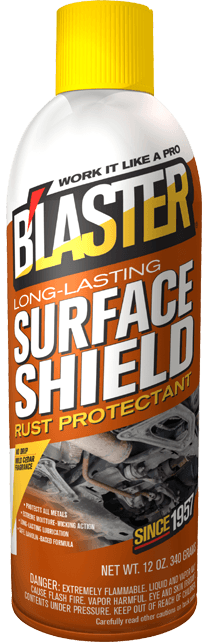

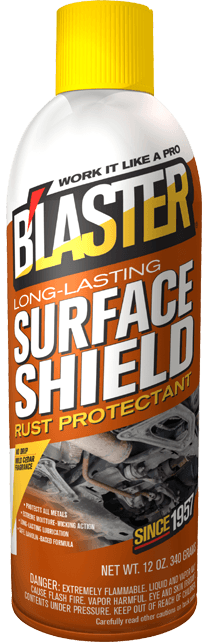

I found this better than the fluid film...although i've had good luck with fluid film but just does not stay as good as this stuff

blasterproducts.com

blasterproducts.com

Surface Shield® Rust Protectant - B'laster Products

B’laster Surface Shield® is the longest lasting, Rust Protectant on the market. This unique formula is easy to apply and provides complete corrosion protection for all metal surfaces, equipment and moving parts. It’s the best defense in fighting rust. Features Extreme Moisture-Wicking Action...

I just picked up a new SnoPro Hybrid aluminum trailer and bought a couple cans of this metal protector and coated the underside aluminum frame and the axle. Time will tell how it holds up.

I am also leading towards that product as well , my only dislike is how it will leave a discolored film, I would rather keep the aluminum brite and be especially on the diamond plate on front of trailer. All of these products listed are good products and all do the same. dingy aluminum is way better than the alternative though. One product I did come across is "sharkskin" metal protectant, anyone heard of this? used it? what do you think?I just picked up a new SnoPro Hybrid aluminum trailer and bought a couple cans of this metal protector and coated the underside aluminum frame and the axle. Time will tell how it holds up.