You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

burned down motor again.... suggestions?

- Thread starter snogoer36

- Start date

I may have found the problem......please confirm or deny.

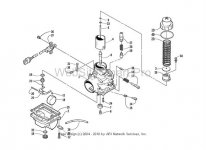

looking at the fuel system and carbs tonight i found that the inlet needle in the carb bowl doesn't have the retainer clip in either carb and all 4 sides of the inlet needle show signs of rubbing 3/4 of the way down the needle. if you lift the float arm with your finger the inlet needle gets stuck up in the needle seat. I have to bang on the side of the carb in order for it to fall down to the tab on the float arm. Both carbs do this, but one of them the inlet needle falls down much easier than the other.

your thoughts?

again thank you very much for all of your help thus far.....

looking at the fuel system and carbs tonight i found that the inlet needle in the carb bowl doesn't have the retainer clip in either carb and all 4 sides of the inlet needle show signs of rubbing 3/4 of the way down the needle. if you lift the float arm with your finger the inlet needle gets stuck up in the needle seat. I have to bang on the side of the carb in order for it to fall down to the tab on the float arm. Both carbs do this, but one of them the inlet needle falls down much easier than the other.

your thoughts?

again thank you very much for all of your help thus far.....

The needles shoud move pretty easy, they may bind slightly w/o fuel to lube them (plus the fuel is under a slight amount of pressure) so they may open just fine when running and bouncing around. It would be wise to replace them since its apart. Not all needles have the clips, so don't worry about it. Replace the needles and seats together as a set though.

I would still check the timing, it's burned down too many times to be an isolated fuel issue. Even a few degrees of advanced timing at the wrong rpm will melt a piston top. Also make sure the pistons are exactly 180 deg. apart. The #1 piston might measure out fine but mark and check them both. ( both plugs fire at the same time, one at top and one at the bottom of the stroke.)

I would still check the timing, it's burned down too many times to be an isolated fuel issue. Even a few degrees of advanced timing at the wrong rpm will melt a piston top. Also make sure the pistons are exactly 180 deg. apart. The #1 piston might measure out fine but mark and check them both. ( both plugs fire at the same time, one at top and one at the bottom of the stroke.)

I had an 03 that stopped running and the cause was a residue in the fuel tank that plugged the inlet screen in the tank. Get a coat hanger and hook onto the fuel line, lifting it off of the bottom of the tank out of the fillport and check the screen. The other problem I had years ago were bad crank seals you might want to pressure check the crank case.

skeeter2010

Member

Yeah I dont really get why he said in the OP that there was a 250 in one carb and a 260 in the other. Unless someone got a hold of this sled who is a NUT about flow matching the intake runners, in which case they may have found the setup with the 250 in it flows more than the other side.

/end nerd

/end nerd

it was common on the older rotax engines to have one carb side slightly richer on the main jet, something to do with heat retention and the clutch . I don't know the exact reason, but they were color coordinated on the carb tops and bodys to the intakes. (pink/blue paint marks) Possible the cats did something similar. One jet size between them is no big deal though. several sizes diff. would make me wonder though.

Possible cause......

I got the new pistons yesterday and started the rebuild, paying close attention to everything. One thing I hadn't noticed before was the block between the carb flange and the block has a crack in it identical on both blocks. This maybe when extra air is getting in? Also noticed that the carb flange was stamped VM32 and i have VM34-588 carbs. The carb goes in the flange a little tight, but it does go in. I ordered all new blocks, flanges, and main jets so both match. I was still thinking about installing the old and doing the unlit propane torch test to see if it truely is sucking air through the crack though. I want to be damn sure this time, don't want to rebuild again.

i also noticed that the plastic washer that goes between the round slide and the e-clip of the needle is gone as well on both carbs. i am thinking correctly this would cause a lean condition as well. the needle clipped on 3 without the washer would be like clipping it on 5.

I got the new pistons yesterday and started the rebuild, paying close attention to everything. One thing I hadn't noticed before was the block between the carb flange and the block has a crack in it identical on both blocks. This maybe when extra air is getting in? Also noticed that the carb flange was stamped VM32 and i have VM34-588 carbs. The carb goes in the flange a little tight, but it does go in. I ordered all new blocks, flanges, and main jets so both match. I was still thinking about installing the old and doing the unlit propane torch test to see if it truely is sucking air through the crack though. I want to be damn sure this time, don't want to rebuild again.

i also noticed that the plastic washer that goes between the round slide and the e-clip of the needle is gone as well on both carbs. i am thinking correctly this would cause a lean condition as well. the needle clipped on 3 without the washer would be like clipping it on 5.