Yeah, I’m thinking he corkscrewed on one or more jumps and landed with all the weight on a single rail tip. These sleds are tail heavy to begin with and when you add rider weight that’s a lot of force.

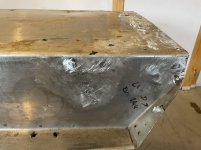

Even after repairing the suspension, I became increasingly suspicious that the entire chassis was also tweaked. The measurements still suggested a twist from front to back. Because of this, I threw out some feelers for a replacement chassis in the spring of 2022. A fellow in Cameron WI said he had a Cyclone chassis and Liquifire chassis that he would let me have for free.

From Baudette MN to Cameron WI is roughly a 650 mile round trip but I added some time/distance by stopping in Duluth to pick up the parts that eventually became the basis for the Mutt.

Anyone that has ever picked up things from vintage sled guys knows you don’t just blow in, get your stuff and get moving. Figure on at least an hour of conversation and looking at what else they have because they usually have a lot of cool stuff.

So, it ended up being about a 15+ hour day and when I got home both the truck and I were out of gas but when I went out the next morning and looked at the haul, it was worth the effort.

Some of you may have seen a similar photo in the Mutt thread but I never explained how or why I came to have a couple of Deere carcasses in the load. At the time, I was trying to decide which project to do next and eventually decided on the Mutt.