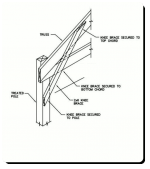

I have a 24x40 pole barn, thinking about using 7/16 OSB on the walls and ceiling then blowing insulation.

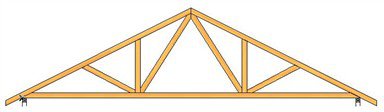

One area I don't fully understand is the ceiling. the trusses are the "Fink" style a "W" between the the lower 2x4 and the upper 2x4's. The trusses 4/12, run the 24' span and are on 4' center.

I don't feel there is enough area to attach the OSB to the trusses with a 4' center without adding more nailers. I was thinking of...

1) running 2x4's under the trusses the length of the barn 40' every two foot then attach the OSB to the 2x4's, using the 2x4's like furring strips.

2) placing 2x4's between the trusses every 2' so the 3.5" width of the 2x4 is vertical like the trusses.

Other options?

The other concern is the extra added weight, using 2x4's, OSB and insulation it's adding ~3.5 # per sq foot.

One area I don't fully understand is the ceiling. the trusses are the "Fink" style a "W" between the the lower 2x4 and the upper 2x4's. The trusses 4/12, run the 24' span and are on 4' center.

I don't feel there is enough area to attach the OSB to the trusses with a 4' center without adding more nailers. I was thinking of...

1) running 2x4's under the trusses the length of the barn 40' every two foot then attach the OSB to the 2x4's, using the 2x4's like furring strips.

2) placing 2x4's between the trusses every 2' so the 3.5" width of the 2x4 is vertical like the trusses.

Other options?

The other concern is the extra added weight, using 2x4's, OSB and insulation it's adding ~3.5 # per sq foot.