indy_500

Well-known member

how many miles do you guys drain and change it? I usually don't go over 500 miles before I change.

I change it whenever I take off the track which is like 3 times a year for stupid reasons LOL

how many miles do you guys drain and change it? I usually don't go over 500 miles before I change.

once a year for me.

This is another "why won't this die" myth.Something I did not read in this thread relates to the chemical capabilities of ATF versus gear oil. ATF will desolve broken down oils where as gear oil will not. I've change oil that is really been black, used the ATF and with the next change it's clean as can be. In fact it's still red. It's an old trick for vehicle engine oil that hasn't been changed regularly. Put a quart in the crankcase, run it for 500 miles, drain and change. You'll be surprised at how it cleans things up.

These aren't piston rings and hi tech engines here...it's a chain case with a couple bearings rollin around and a chain.

Not high pressure, High temperature, High friction....situation.

Run peanut oil in there if you want to. If you have a diamond drive...I would use the recommended stuff. Otherwise, whatcha got on the shelf will do fine. Thinner the better If it leaks out...you have a problem that needs fix'n...no matter what you put in there.

Drain it once a year to get any moisture that worked into the box out and load with clean fresh stuff...as long as it is a lubricant it will work just fine.

Wouldn't anti foaming be a plus?

On a Poo you also have a bearing and a seal coming into the chain case. Rubber seals react differently with different oils. My brother in law put regular 30 weight motor oil in has chaincase and it foamed and built preasure enough to blow out the cover seal. He was running around 80plus most the day up in Canada and seal went 60 miles from town. We were on a seven day backpack trip. We used his toothpaste as a seal and his extra qt. Of two stroke to get us into Hearst. Dealer laughed and said, "Well it got ya outta da bush ay!". Sled was an 02 xcsp 800 with a reusable rubber gasket and it puffed up, so the rubber did have a reacting to the oil he used.

Wayne all that you are lubing on a standard chain case is the chain because there is two sealed bearings. ATF will get into the rollers on the chain easier than the gear case lube which in turn causes the chain to be better lubed. The oil seals on the case are to keep the oil in and the bearing uses no lube.

That isn't how this works WJ...

Most guys have a quart or two of tranny fluid on the shelf. You have to go to the sled store and buy a container of the OEM stuff recommended which has been marked up in price by the fluid maker, then the sled maker for putting their name on the stuff, and then the dealer gets to double the price and stock it.

Never mind you have to spend the money and time to drive to the dealership to get it.

Meanwhile the so called "engineering" you refer to is scant...as they don't call the oil company and have one "designed" specifically for this machine, but pull a chart, look at the specs and decide what is already available that will work well.

This is America, and we are led to believe that ONLY one product will work in such applications when in truth probably every product made will work. Worst case scenario, you find some special rubber gasket that decides to implode when in contact with anything other than the intended lube and you have to replace the gasket...or if you ignore it, a chain and bearing over time.

This isn't heart surgery here....it is a bearing and chain rolling around and needing a bit of friction fighting.

So keep it all in perspective. It is NOT worth getting your shorts in a bind over! btw, welcome to the board!

Unfricken believable how some of you people try try to reengineer the chain case fluid/oil capabilities to possibly save a few bucks and risk costing a thousand. Engineers designed chain cases and oil compatabilities for a reason. For the cost of a quart of mfg recommended chain case oil???? ***?? W.T.F.?

That isn't how this works WJ...

Most guys have a quart or two of tranny fluid on the shelf. You have to go to the sled store and buy a container of the OEM stuff recommended which has been marked up in price by the fluid maker, then the sled maker for putting their name on the stuff, and then the dealer gets to double the price and stock it.

Never mind you have to spend the money and time to drive to the dealership to get it.

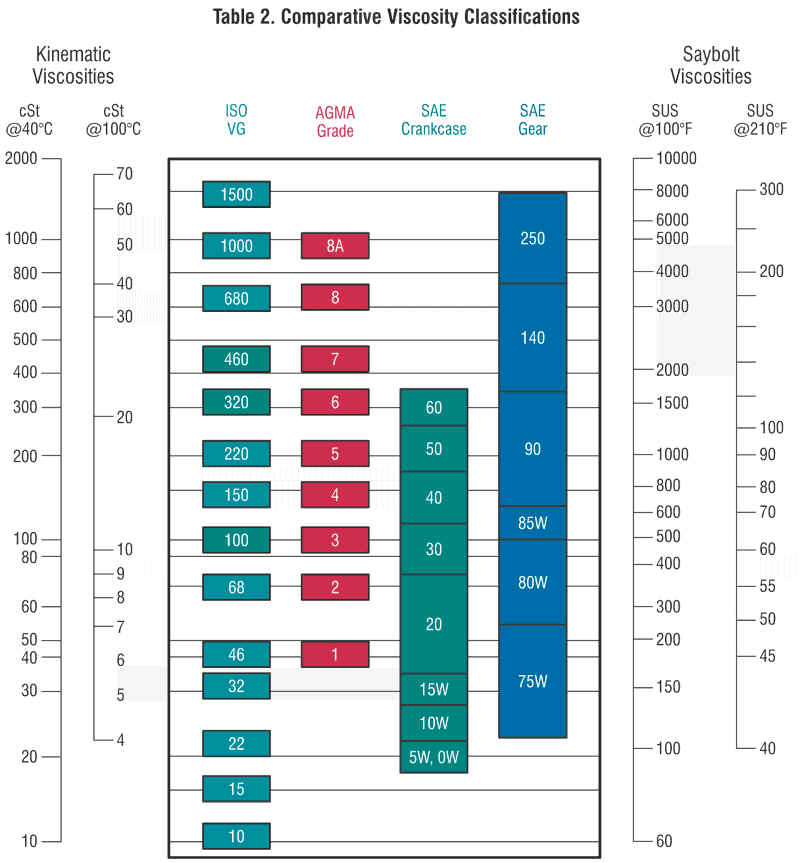

Meanwhile the so called "engineering" you refer to is scant...as they don't call the oil company and have one "designed" specifically for this machine, but pull a chart, look at the specs and decide what is already available that will work well.

This is America, and we are led to believe that ONLY one product will work in such applications when in truth probably every product made will work. Worst case scenario, you find some special rubber gasket that decides to implode when in contact with anything other than the intended lube and you have to replace the gasket...or if you ignore it, a chain and bearing over time.

This isn't heart surgery here....it is a bearing and chain rolling around and needing a bit of friction fighting.

So keep it all in perspective. It is NOT worth getting your shorts in a bind over! btw, welcome to the board!