skiroule

Well-known member

Another diversion of the best kind. An old riding buddy from the Cities made a trip north to visit his parents in the area so we were able to put in a day on the sleds.

As I’m sure I’ve said multiple times before, after at least two years of almost no riding of any kind, it sure feels good to be on a sled again. We rode creek beds, swamps, brush, trees, power lines, rivers, logging roads, fields, and even a little trail. The snow was a typical spring mix of set-up, windblown, and pillow soft and it was all a blast to ride. The photos do a better job of describing the experience.

I’ve always had this mindset that if I get something done on a project every week, no matter how small, it will eventually get done. I guess it states the obvious but it keeps me from getting discouraged and it certainly applies from time to time.

I did get a couple of spindle arm stops made to replace the welded-on ones that were either sheared off or cracked.. This aluminum is very strong, if these break, I’ve got bigger problems than a broken stop.

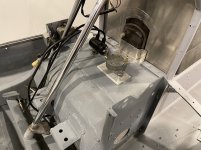

Since this is a whole different engine configuration for this sled, I wanted to make sure there is no interference between things under the hood so I did a test-mount of the CDI box, voltage regulator, coil, and fuel pump. These will basically be a bolt-in now, once the chassis is painted. It sure seems simple compared to modern sleds.

In the “Little Victories” department, I finally won the battle with the pin in the hood piano hinge. Looking at it now, I can’t believe how hard it was to get out. This thing was stuck, stuck. It took penetrating oil, heat, and all the patience I could muster to remove it.

As I’m sure I’ve said multiple times before, after at least two years of almost no riding of any kind, it sure feels good to be on a sled again. We rode creek beds, swamps, brush, trees, power lines, rivers, logging roads, fields, and even a little trail. The snow was a typical spring mix of set-up, windblown, and pillow soft and it was all a blast to ride. The photos do a better job of describing the experience.

I’ve always had this mindset that if I get something done on a project every week, no matter how small, it will eventually get done. I guess it states the obvious but it keeps me from getting discouraged and it certainly applies from time to time.

I did get a couple of spindle arm stops made to replace the welded-on ones that were either sheared off or cracked.. This aluminum is very strong, if these break, I’ve got bigger problems than a broken stop.

Since this is a whole different engine configuration for this sled, I wanted to make sure there is no interference between things under the hood so I did a test-mount of the CDI box, voltage regulator, coil, and fuel pump. These will basically be a bolt-in now, once the chassis is painted. It sure seems simple compared to modern sleds.

In the “Little Victories” department, I finally won the battle with the pin in the hood piano hinge. Looking at it now, I can’t believe how hard it was to get out. This thing was stuck, stuck. It took penetrating oil, heat, and all the patience I could muster to remove it.