skiroule

Well-known member

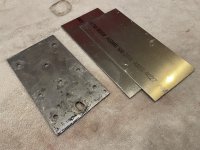

At first I thought it would just buff out but then I figured it maybe needed paint.a little paint and that looks great

It’s not always the case but more often than not I’m amazed at how well some of the parts on these old sleds have held up. Not only did these sleds put on some hard miles but a good share of them ended up sitting in a field for 30 – 40 years, exposed to whatever mother nature could throw at them.It's amazing what the condition of the idlers are in just like the track bands are. It's too bad that things can't be made to last as long anymore, or, should I say, aren't made to last anymore. Like I said in my previous post, the magic man strikes again.

This is the final piece of the puzzle with regard to the “under tunnel” running gear. Track, suspension, and driveshaft are all finished. Now I anticipate spending an extended period of time doing metal work on the bare chassis. I wouldn’t be shocked if it takes a month or more. It needs a lot of love. I’ll try to work in other things if for some reason I have some down time on the chassis.

Can't really get the light colored drivers totally clean but as I mentioned in an earlier post, they have surprisingly little wear.